Maintenance Tips to Extend the Lifespan of Cast Metal Parts Part Two

2025-10-13

Benefits and challenges of investment casting 2

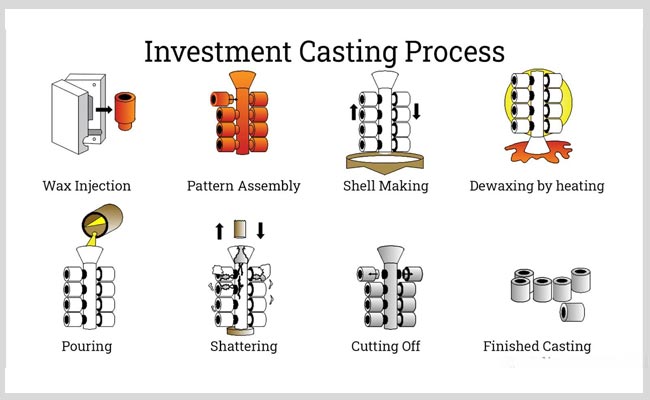

2025-10-27Investment casting, also known as lost-wax casting, is a precision manufacturing process used to produce complex metal parts with high accuracy and excellent surface finish. While widely used across industries such as aerospace, automotive, medical, and industrial machinery, it comes with both advantages and limitations.

Benefits of Investment Casting

High Dimensional Accuracy and Tight Tolerances

Investment casting offers excellent dimensional control, making it ideal for precision components that require tight tolerances without excessive machining.

Complex Geometries

Intricate shapes, thin walls, and internal cavities that are difficult or impossible with other methods can be achieved thanks to the wax pattern and ceramic mold process.

Superior Surface Finish

The process produces smooth surface finishes (typically 125 RMS or better), reducing or eliminating the need for post-processing.

Material Versatility

A wide range of metals and alloys can be used, including stainless steels, tool steels, aluminum, bronze, titanium, and superalloys.

Minimal Material Waste

Compared to machining from solid stock, investment casting generates less scrap, contributing to cost-efficiency and sustainability.

Near-Net-Shape Production

Parts often come out close to final shape, reducing the amount of secondary machining required.

Design Flexibility

Engineers can incorporate logos, holes, threads, or text directly into the cast without additional operations.