Anchor Foundation System

2020-11-11

Anodizing for Wood Machinery Parts

2020-12-08Casting Defect Definitions

Regular Gas Blow:

Smooth, very round, bowl shaped

Bottom can be seen with the eye

Size and depth are easy to determine

Usually a singular defect

Irregular Gas Blow:

Bottom can be seen with the eye

Depth is easy to determine

Typically, multiple defects within a small area

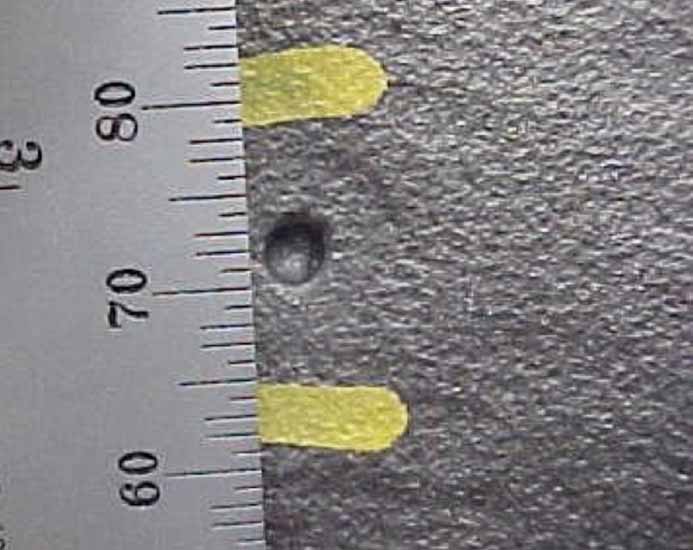

Pin Hole:

Smooth, very round, ‘black’ hole

Bottom of can NOT be seen with the eye

Size and depth are easy to determine

Inclusion - Slag:

Irregular shaped

Approximate 50/50 ratio of porosity and clean machined surface

Defect area is usually larger than 5x5mm and can be as large as 10x10mm

Needs to be analyzed by a trained metallurgist

Sand Inclusion:

Irregular shaped

Jagged edges

Loose material can be easily removed

Exact size and depth difficult to determine

Handling Damage

Handling Damage:

Occurs after the casting has reached the solid state

Usually accompanied by physical markings

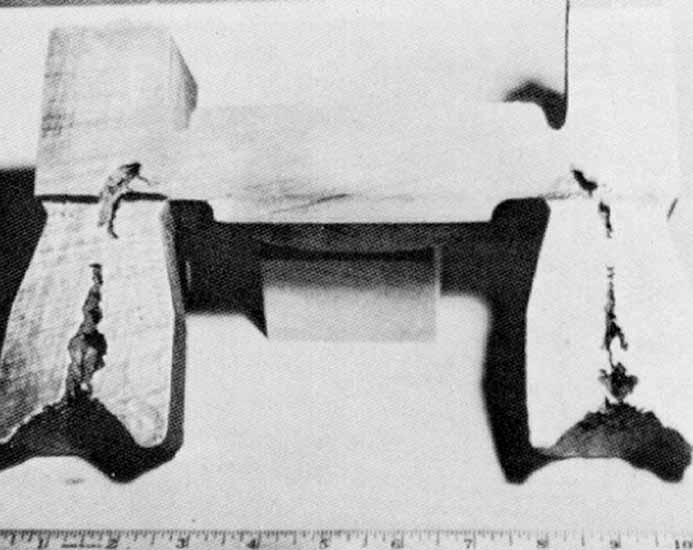

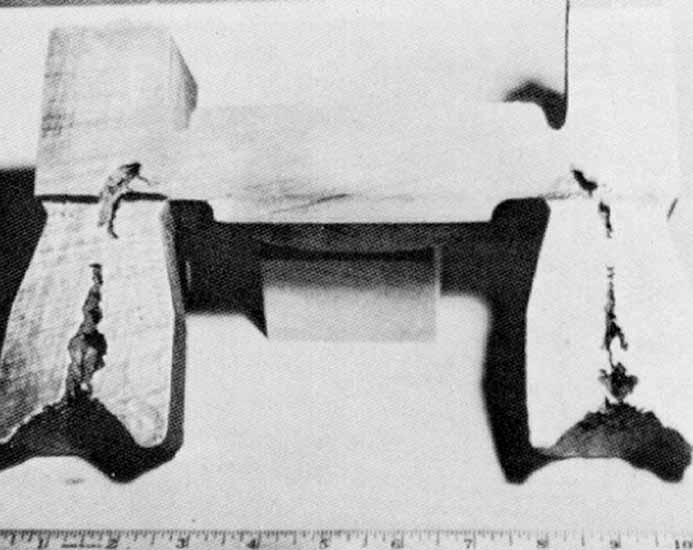

Hot Tears

Hot Tears:

Occurs when a tear or crack occurs before the metal has reached a solidified state

Includes an oxide film in the tear region

Often in areas of section size transition

Needs to be analyzed by a trained metallurgist

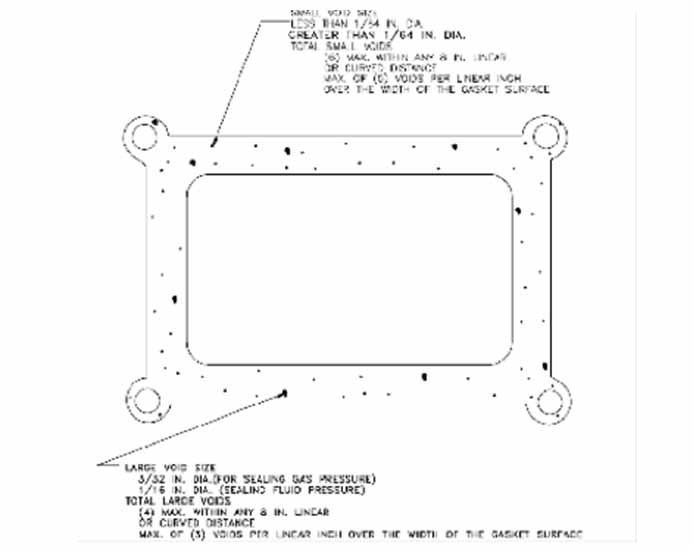

Salt & Pepper Porosity

Salt & Pepper Porosity :

Widely dispersed, very small porosity visible on machined surfaces

Common in aluminum alloys (hydrogen gas porosity)

Typically not interconnected (will not form a leak path)

Fins or Veining

Fins or Veining:

Occurs when cores crack from handling or in the mold

May block internal passages

Typically adhere strongly to the casting, but may be broken off

Shrink Porosity

Shrink Porosity:

Occurs when thin and thick geometries intersect and uneven cooling occurs

Other Defects:

Dimensional defect

• Occurs when the physical dimensions of the casting do not meet the specifications

Material properties

• The chemical properties do not meet the specifications

• The mechanical properties (tensile strength) do not meet the specifications

• Microstructural formations

• When the molecules do not form the proper microstructure

Burned-in sand

• Sand adheres firmly to the surface of the casting

• Most common in ferrous metals (iron, steel) and in pockets, corners or small passages

Cleanliness defects

• Occurs when sand is not sufficiently cleaned from the casting

Related posts

What Are Alloying Elements

2020-02-07Compatibility Chart of Materials Versus Processes

2020-02-07Casting Defect Definitions

Regular Gas Blow:

Smooth, very round, bowl shaped

Bottom can be seen with the eye

Size and depth are easy to determine

Usually a singular defect

Irregular Gas Blow:

Bottom can be seen with the eye

Depth is easy to determine

Typically, multiple defects within a small area

Pin Hole :

Smooth, very round, ‘black’ hole

Bottom of can NOT be seen with the eye

Size and depth are easy to determine

Inclusion - Slag:

Irregular shaped

Approximate 50/50 ratio of porosity and clean machined surface

Defect area is usually larger than 5x5mm and can be as large as 10x10mm

Needs to be analyzed by a trained metallurgist

Sand Inclusion:

Irregular shaped

Jagged edges

Loose material can be easily removed

Exact size and depth difficult to determine

Handling Damage:

Occurs after the casting has reached the solid state

Usually accompanied by physical markings

Hot Tears:

Occurs when a tear or crack occurs before the metal has reached a solidified state

Includes an oxide film in the tear region

Often in areas of section size transition

Needs to be analyzed by a trained metallurgist

Salt & Pepper Porosity :

Widely dispersed, very small porosity visible on machined surfaces

Common in aluminum alloys (hydrogen gas porosity)

Typically not interconnected (will not form a leak path)

Fins or Veining :

Occurs when cores crack from handling or in the mold

May block internal passages

Typically adhere strongly to the casting, but may be broken off

Shrink Porosity:

Occurs when thin and thick geometries intersect and uneven cooling occurs

Other Defects:

Dimensional defect

• Occurs when the physical dimensions of the casting do not meet the specifications

Material properties

• The chemical properties do not meet the specifications

• The mechanical properties (tensile strength) do not meet the specifications

• Microstructural formations

• When the molecules do not form the proper microstructure

Burned-in sand

• Sand adheres firmly to the surface of the casting

• Most common in ferrous metals (iron, steel) and in pockets, corners or small passages

Cleanliness defects

• Occurs when sand is not sufficiently cleaned from the casting