The Role of Ductile Iron in Durable Industrial Components

2025-06-09

Common Casting Defects: Porosity, Shrinkage, and More Part Two

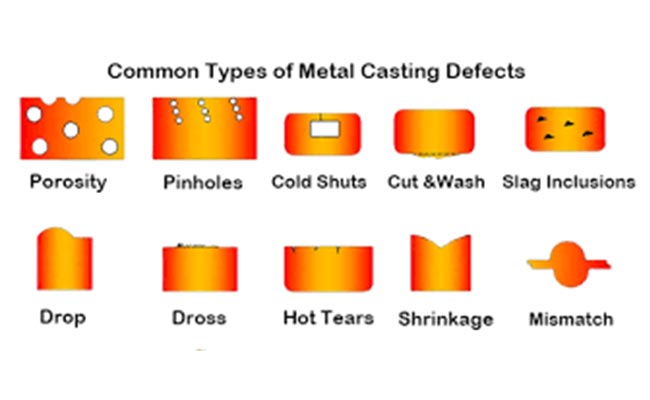

2025-06-23Casting is one of the most widely used manufacturing processes for producing metal parts, but like any complex technique, it’s not without its challenges. Casting defects can occur due to various factors—material choice, temperature control, mold design, and more. Understanding the common defects and their causes can help manufacturers improve their processes, reduce scrap, and enhance product quality. Let’s explore some of the most common casting defects, including porosity, shrinkage, and others.

1. Porosity

Porosity refers to the formation of small voids or gas pockets within a cast metal part. These voids can be either internal or on the surface of the component, and they weaken the material, leading to potential structural failures.

Causes: Porosity can occur due to trapped air or gases during the solidification process, insufficient ventilation in the mold, or improper gating systems that prevent the molten metal from flowing smoothly. In some cases, impurities in the metal, like moisture or dirt, can cause gas to be released during casting.

Solution: To prevent porosity, it’s essential to improve mold ventilation, use degassed or cleaner metals, and ensure proper gating and riser design. Using a vacuum casting system or pressure die casting can also reduce the risk.

2. Shrinkage

Shrinkage occurs when the metal cools and contracts, leading to cavities or cracks in the final cast product. This defect typically happens in thick sections where the cooling rate is uneven, causing the metal to shrink inwards.

Causes: Shrinkage is mainly caused by the metal solidifying and losing volume as it cools. If the mold is not properly designed with enough risers or feeders to compensate for this volume change, shrinkage cavities can form.

Solution: The best way to mitigate shrinkage is by optimizing the mold design, ensuring that the risers and feeders are correctly positioned to feed molten metal into areas prone to shrinkage. Additionally, controlling the cooling rate of the metal can help prevent excessive shrinkage.

3. Cold Shut

A cold shut occurs when two streams of molten metal meet but do not fully fuse together, leaving a weak seam or line in the cast component. This can significantly reduce the mechanical properties of the part.

Causes: Cold shuts happen when the molten metal solidifies before the two flows have completely joined. This can be due to improper pouring temperature, inadequate gating design, or low pouring speed.

Solution: To reduce the risk of cold shuts, manufacturers should ensure the correct pouring temperature and use a mold design that promotes smooth, continuous flow of molten metal. Using a well-optimized gating system can also help prevent cold shut issues.

4. Hot Tears

Hot tears, also known as hot cracks, are cracks that form in a casting as it cools and solidifies. These defects occur when the metal is still in a semi-solid state but experiences internal stresses due to uneven cooling or excessive shrinkage.

Causes: Hot tears are often caused by uneven cooling rates, design issues, or excessive shrinkage stresses in the mold. Thin sections of the casting or inadequate venting can exacerbate this problem.

Solution: The design of the casting should minimize thin sections and provide enough space for the metal to solidify without experiencing high stresses. Adding appropriate fillets and using controlled cooling techniques can reduce the occurrence of hot tears.