Common Casting Defects: Porosity, Shrinkage, and More Part One

2025-06-16

Meeting ISO Standards: Why Certification Matters in Metal Casting Part One

2025-06-305. Misruns

A misrun occurs when the molten metal solidifies before it fills the entire mold cavity. This leaves an incomplete or partially filled casting, which can be a serious defect, especially for parts that require precise dimensions and structure.

Causes: Misruns happen when the molten metal does not have enough fluidity to completely fill the mold. This is often due to low pouring temperatures, insufficient metal volume, or poor mold design.

Solution: To avoid misruns, it’s important to ensure that the molten metal is poured at the proper temperature and that the mold is adequately designed to allow for smooth, uninterrupted metal flow. Using risers and optimizing the gating system can help prevent misruns.

6. Sand Inclusion

Sand inclusion occurs when sand from the mold gets embedded in the final cast product. This defect can weaken the casting and affect the surface finish, making it unsuitable for some applications.

Causes: Sand inclusion typically results from the breakdown of the sand mold during casting. When the molten metal comes into contact with the mold’s sand core, it can cause pieces of sand to detach and get trapped in the final casting.

Solution: Ensuring that the mold is properly hardened and reinforced can prevent sand inclusion. Additionally, using the correct sand mixture and carefully controlling the pouring process can minimize this defect.

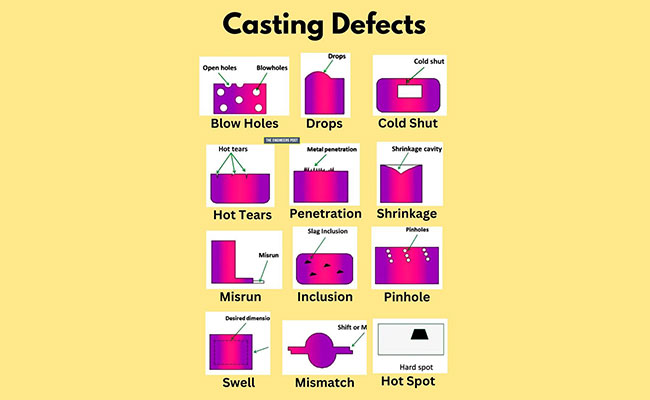

7. Blowholes

Blowholes are similar to porosity but occur when gas becomes trapped beneath the surface of the casting. They are usually larger and can significantly weaken the casting.

Causes: Blowholes can be caused by trapped gases from the metal, mold, or core material, often due to poor venting or mold permeability. Another contributing factor is the use of improper materials that release gases when exposed to molten metal.

Solution: Improving venting in the mold and ensuring the use of high-quality, low-gassing metal alloys can help prevent blowholes. Additionally, ensuring the mold material is well-prepared and free of moisture can reduce gas entrapment.

Conclusion

Casting defects like porosity, shrinkage, cold shuts, and others are common challenges in metal casting that can impact product quality and performance. By understanding the causes of these defects and implementing the right solutions—such as optimizing mold designs, controlling pouring temperatures, and improving material quality—manufacturers can reduce defects, improve yields, and produce high-quality cast components. Consistent monitoring, quality control, and advances in casting technology continue to help overcome these challenges, ensuring the reliability and durability of cast parts across various industries.