Hello, 2026! | A New Year, A Fresh Chapter

2026-01-06

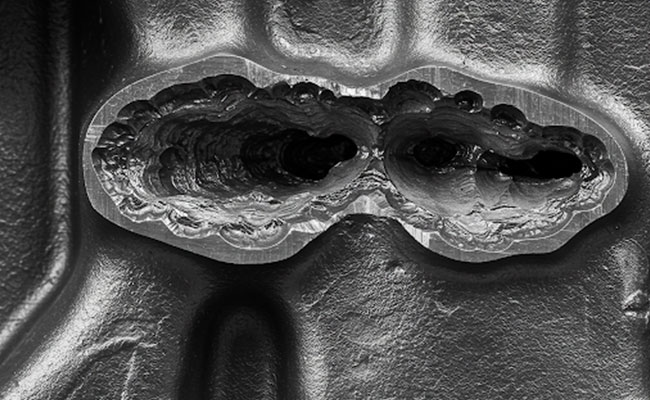

Reducing Waste in Foundry Operations

2026-01-19Energy-efficient techniques in casting aim to reduce the energy consumption and environmental impact of metal casting processes while maintaining or improving product quality. Here are several effective methods and innovations:

🔧 1. Process Optimization

a. Efficient Melting Techniques

Induction Furnaces: More efficient than traditional fuel-fired furnaces due to better control and reduced heat losses.

Regenerative Burners: Recover waste heat from flue gases to preheat combustion air.

Preheating Charge Materials: Reduces the energy required to melt scrap by using waste heat to preheat it.

b. Real-Time Monitoring & Control

Use of IoT sensors and automated controls to optimize furnace temperature and pouring time.

Energy management systems (EMS) to track and reduce peak demand.

🔁 2. Waste Heat Recovery

Heat Recovery Units: Recycle heat from furnace exhausts to preheat combustion air or feed water.

Recuperators & Regenerators: Capture and reuse waste heat effectively.

🧱 3. Improved Insulation and Furnace Design

Use of high-performance refractory materials to minimize heat losses.

Modular furnace designs that reduce heat radiation and improve thermal efficiency.

Covering molten metal with insulating materials to reduce surface heat loss.

🔄 4. Recycling and Reuse

Recycling of foundry sand and metal scraps to reduce raw material processing energy.

Reuse of exothermic risers and other expendable materials.

⚙️ 5. Near-Net Shape Casting

Techniques like investment casting, die casting, and lost foam casting produce components close to final dimensions, reducing the need for machining and associated energy.

🧪 6. Advanced Materials and Alloys

Use of low-melting-point alloys when feasible to reduce melting energy.

Development of self-lubricating or self-solidifying alloys that can reduce post-processing.

🏭 7. Cleaner Production Techniques

Vacuum casting and inert atmosphere casting can reduce oxidation losses, leading to better yields and lower energy per unit of output.

Adoption of lean manufacturing principles to minimize energy waste across the value chain.

🌱 8. Renewable Energy Integration

Solar thermal systems for preheating.