How Casting Designs Affect Production Efficiency I

2026-02-025. Easing Mold Removal and Post-Processing

Adding proper draft angles and avoiding unnecessary flat or tight surfaces can greatly ease the ejection of a casting from its mold. It also reduces the effort required during cleaning, trimming, and finishing. This simple design consideration can save significant time and labor during the post-casting stage.

6. Enabling Reusability and Standardization

Designs that align with standard core and mold elements are more efficient to produce, especially in high-volume runs. Standardized features and modular tooling also enhance reusability, cutting down on the need for frequent pattern changes or new molds.

7. Supporting Automation and Machining

Modern foundries increasingly rely on automation and CNC machining to improve throughput and consistency. Casting designs that consider downstream processes—like machine fixturing and robotic handling—enable smoother transitions between stages and greater integration into automated workflows.

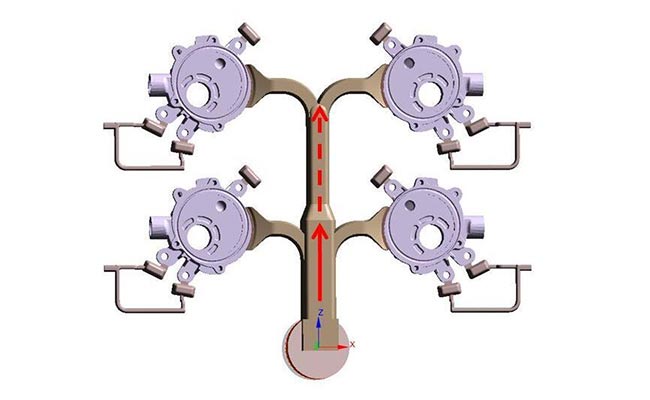

8. Increasing Yield and Reducing Waste

An efficient design leads to higher yield by minimizing the volume of metal lost in runners, risers, and sprues. A well-planned layout, combined with optimized gating systems, ensures that more of the molten metal becomes usable product, reducing waste and improving overall process efficiency.

Final Thoughts

Casting design is a critical link between engineering intent and production reality. By focusing on efficient, manufacturable designs, companies can lower production costs, reduce lead times, and improve product quality—all without compromising performance.

For foundries and design engineers alike, collaboration early in the design phase is key to unlocking the full potential of casting efficiency.