Benefits and challenges of investment casting 2

2025-10-27

How does molten metal solidify in casting foundry Part Two

2025-11-10In a casting foundry, molten metal solidifies in a mold to form a specific shape or part. The solidification process in a foundry typically happens in several stages and is influenced by factors like the type of metal, mold material, cooling rate, and the design of the casting. Here’s a detailed breakdown of how it works in a foundry setting:

1. Pouring the Molten Metal into the Mold

Once the metal has been heated to a molten state (usually in a furnace), it’s poured into a mold cavity. The mold can be made from various materials, such as sand (for sand casting), metal (for die casting), or ceramic (for investment casting).

The molten metal is typically poured from a ladle or similar device, and the goal is to fill the mold completely before it starts to cool and solidify.

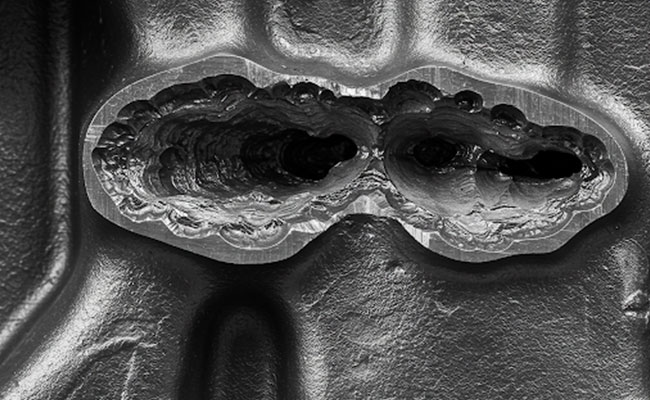

2. Initial Cooling at the Mold Surface (Solidification Begins)

When the molten metal comes in contact with the cooler mold surface, heat transfers from the molten metal to the mold. This cooling causes the outermost layer of metal to begin solidifying almost immediately.

This layer of solidified metal is known as the skin, and it forms a protective boundary around the liquid metal inside.

The solidification of this layer begins the crystallization process in the metal.

3. Nucleation and Crystal Growth

After the initial solidification of the outer layer, the molten metal begins to cool more deeply. At this stage, nucleation (the formation of tiny solid particles or crystals) begins in the liquid metal, particularly near the solidified skin.

These nucleation sites grow into larger crystals, and this process continues until the metal is fully solid. The rate of cooling and the presence of any impurities in the metal can affect how the crystals form and how large they get.

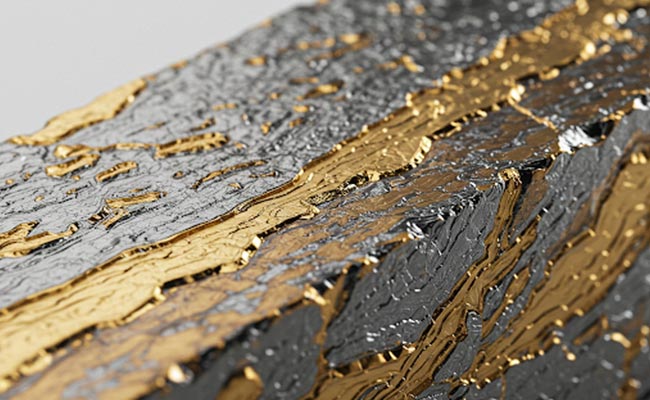

4. Directional Solidification

In most castings, solidification doesn’t happen uniformly throughout the entire mold. Instead, solidification typically starts at the mold walls and proceeds toward the center of the casting. This is called directional solidification.

A key goal in casting design is to ensure that the metal solidifies in a controlled way to avoid defects. For example, casting designers will often use risers and gates to direct the flow of molten metal and allow the center of the casting to remain molten longer, ensuring that it fills properly and solidifies last.