Alloy compositions and their impact on casting performance Part Two

2025-12-08

Innovations in mold materials and processes

2025-12-22Casting defects are imperfections that occur during the casting process, affecting the quality and integrity of the final product. Fortunately, many of these defects can be corrected or prevented with the right techniques and adjustments. Here’s a breakdown of common casting defects and how to address them:

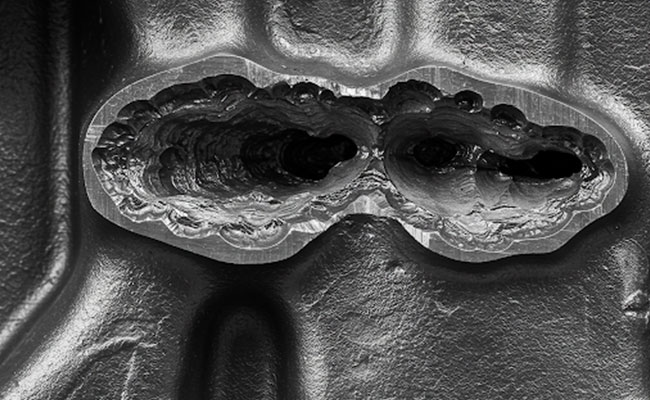

1. Porosity

- What it is: Tiny voids or holes in the casting caused by trapped gases or shrinkage during solidification.

- How to fix it:

- Improve mold venting: Ensure proper escape for gases during pouring.

- Control pouring temperature: Adjust to minimize gas absorption.

- Use high-quality sand: Opt for sand with good permeability.

- Degas molten metal: Remove dissolved gases before pouring.

2. Inclusions

- What it is: Foreign particles (slag, dross, sand) trapped in the casting.

- How to fix it:

- Improve melting practices: Use flux to remove impurities.

- Clean mold thoroughly: Remove loose particles before pouring.

- Use filters in the gating system: Trap inclusions during pouring.

3. Shrinkage Defects

- What it is: Cavities or depressions caused by the metal contracting as it solidifies.

- How to fix it:

- Design proper gating system: Ensure continuous metal flow.

- Use risers: Provide extra metal to compensate for shrinkage.

- Control cooling rates: Promote uniform solidification.

4. Surface Defects

- What it is: Imperfections on the casting surface, such as cracks, rough texture, or cold shuts.

- How to fix it:

- Optimize pouring technique: Control speed and temperature.

- Improve mold quality: Ensure smooth surface and proper compaction.

- Adjust gating system: Prevent turbulence and ensure smooth flow.

5. Dimensional Inaccuracies

- What it is: Casting dimensions deviating from the intended specifications.

- How to fix it:

- Use accurate patterns and molds: Ensure precise dimensions.

- Control casting parameters: Adjust temperature, pressure, and cooling rates.

- Proper mold assembly: Ensure proper alignment of mold parts.

General Tips for Correcting and Preventing Casting Defects

- Thoroughly inspect castings: Identify defects early to take corrective action.

- Analyze the causes: Understand the root cause of defects to implement effective solutions.

- Optimize casting process: Fine-tune parameters like pouring temperature, speed, and cooling rates.

- Use high-quality materials: Employ quality molds, sand, and molten metal.

- Maintain equipment: Ensure equipment is in good working condition.

- Train personnel: Educate workers on proper casting techniques and defect prevention.

By understanding the causes of casting defects and implementing the appropriate corrective measures, manufacturers can significantly improve the quality and yield of their casting processes.