News

MAXWILL NEWS

2026-01-26

🌍 Benefits of Recycling Metals in Foundries 1. Environmental Sustainability Reduces the need for mining and processing virgin ores Lowers […]

2026-01-19

🔧 1. Raw Material Optimization Metal Recycling: Reuse sprues, runners, and rejected castings internally. Accurate Alloying: Use only necessary amounts […]

2026-01-12

Energy-efficient techniques in casting aim to reduce the energy consumption and environmental impact of metal casting processes...

2026-01-06

As the clock struck midnight and fireworks lit up the sky, we welcomed not just another year—but a brand new […]

2025-12-29

As we look forward to the holiday season of 2025, I wish you a time filled with joy, connection, and peace. May your days be bright...

2025-12-22

These innovations are helping to improve the quality, efficiency, and sustainability of the molding process...

2025-12-15

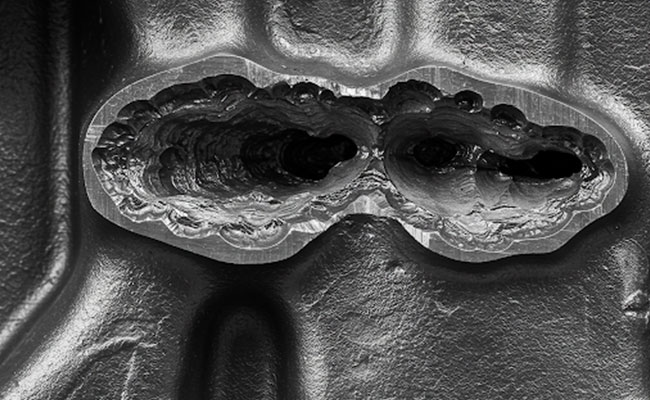

Casting defects are imperfections that occur during the casting process, affecting the quality and integrity of the final product. Fortunately, […]

2025-12-08

4. Mechanical Properties 5. Defects 6. Casting Techniques and Alloy Composition 7. Corrosion Resistance In Summary: The alloy composition has […]

2025-12-01

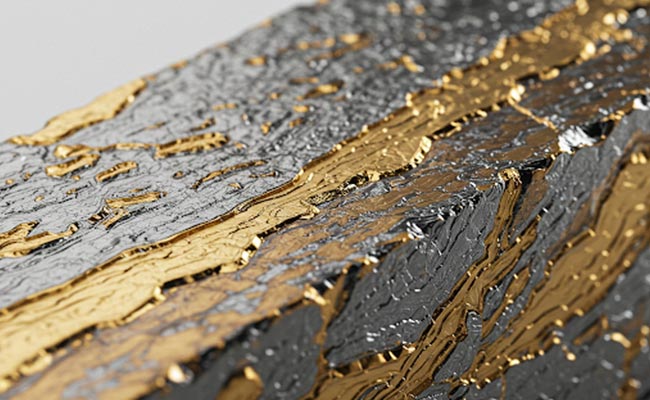

The composition of an alloy plays a significant role in its casting performance and directly influences properties such as strength, […]