Reducing Waste in Foundry Operations

2026-01-19🌍 Benefits of Recycling Metals in Foundries

1. Environmental Sustainability

Reduces the need for mining and processing virgin ores

Lowers greenhouse gas emissions

Cuts down on landfill waste

2. Cost Savings

Recycled metals are often cheaper than new materials

Energy savings from melting scrap instead of raw ore can be up to 95% for some metals

3. Operational Efficiency

Minimizes waste disposal needs

Enhances furnace yield with optimized charge materials

Streamlines inventory management

⚙️ Key Steps in the Recycling Process

🔹 Collection and Segregation

Different types of metal (ferrous and non-ferrous) must be separated for effective recycling. Impurities like coatings, rust, or non-metal materials are removed.

🔹 Preparation and Sizing

The scrap is cleaned and sometimes shredded or cut into smaller pieces for efficient melting.

🔹 Melting

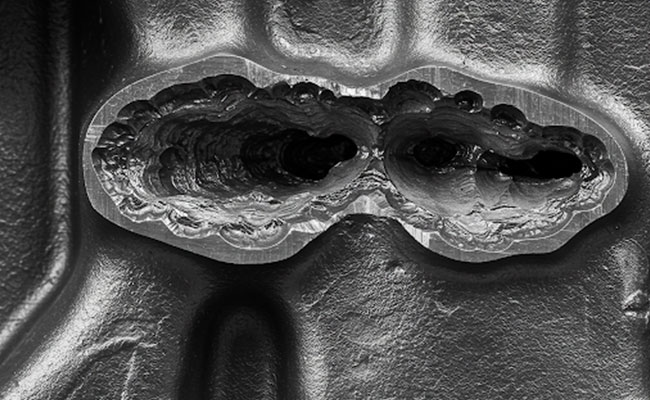

The scrap is melted in induction, cupola, or electric arc furnaces. Additives or fluxes may be introduced to improve metal quality.

🔹 Refining and Alloying

Adjustments are made to meet specific material specifications, ensuring consistency in the final cast products.

🔹 Casting and Reuse

The refined molten metal is poured into molds to create new components, restarting the product life cycle.

🧠 Best Practices for Foundries

Invest in high-quality sorting and separation systems to improve scrap purity.

Use melt shop management software to track scrap composition and optimize charge mixes.

Maintain regular furnace maintenance to avoid contamination and increase melt efficiency.

Partner with reliable scrap suppliers to ensure consistent quality and volume.

Educate staff on identifying recyclable materials and avoiding contamination.