Forging used in automobile industry

2025-05-26

The Role of Ductile Iron in Durable Industrial Components

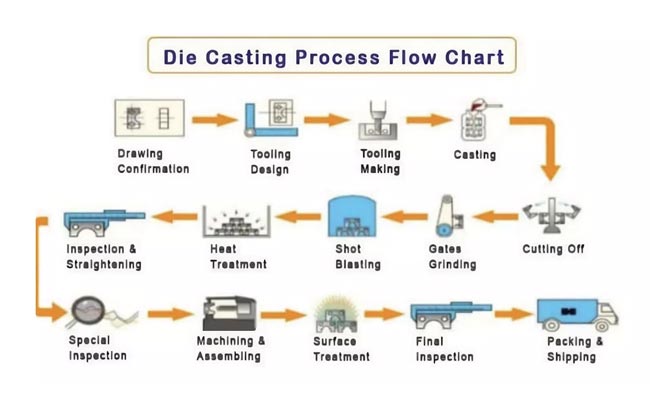

2025-06-09Die casting has long been a cornerstone of manufacturing, enabling the production of complex, high-precision parts at high volumes. Over the years, the process has evolved dramatically, integrating new technologies and materials to meet the growing demands of modern industries, from automotive to electronics.

Advancements in Materials and Techniques

As industries grew more sophisticated, so did the die casting process. Newer, lighter alloys like aluminum, magnesium, and zinc replaced traditional materials, offering better strength-to-weight ratios and corrosion resistance. Innovations like cold chamber and hot chamber die casting further refined the process, allowing manufacturers to handle a broader range of metals and achieve finer tolerances.

Precision Engineering and Automation

In recent decades, the rise of precision engineering and automation has been a game-changer. Today’s die-casting machines are equipped with advanced sensors and robotic systems, ensuring greater precision and repeatability. Computer-aided design (CAD) and computer-aided manufacturing (CAM) tools allow for better mold design and optimization, while simulation software predicts potential flaws before production even begins.

Sustainability and Green Manufacturing

As sustainability becomes a growing concern, die casting has adapted by incorporating energy-efficient technologies and recycling practices. The use of recycled metals and reducing scrap rates through more precise processes has minimized the environmental footprint, making die casting a more eco-friendly solution.

The Future: Smart Die Casting

Looking ahead, the future of die casting lies in integrating smart technologies such as the Internet of Things (IoT) and artificial intelligence (AI). These technologies can monitor and adjust the die casting process in real time, ensuring even greater levels of efficiency and accuracy.

In conclusion, die casting has come a long way from its humble beginnings. Today, it remains a vital tool for producing high-precision, high-volume parts. With continuous advancements in materials, automation, and sustainability, the future of die casting is poised to deliver even more innovative solutions for modern manufacturing needs.